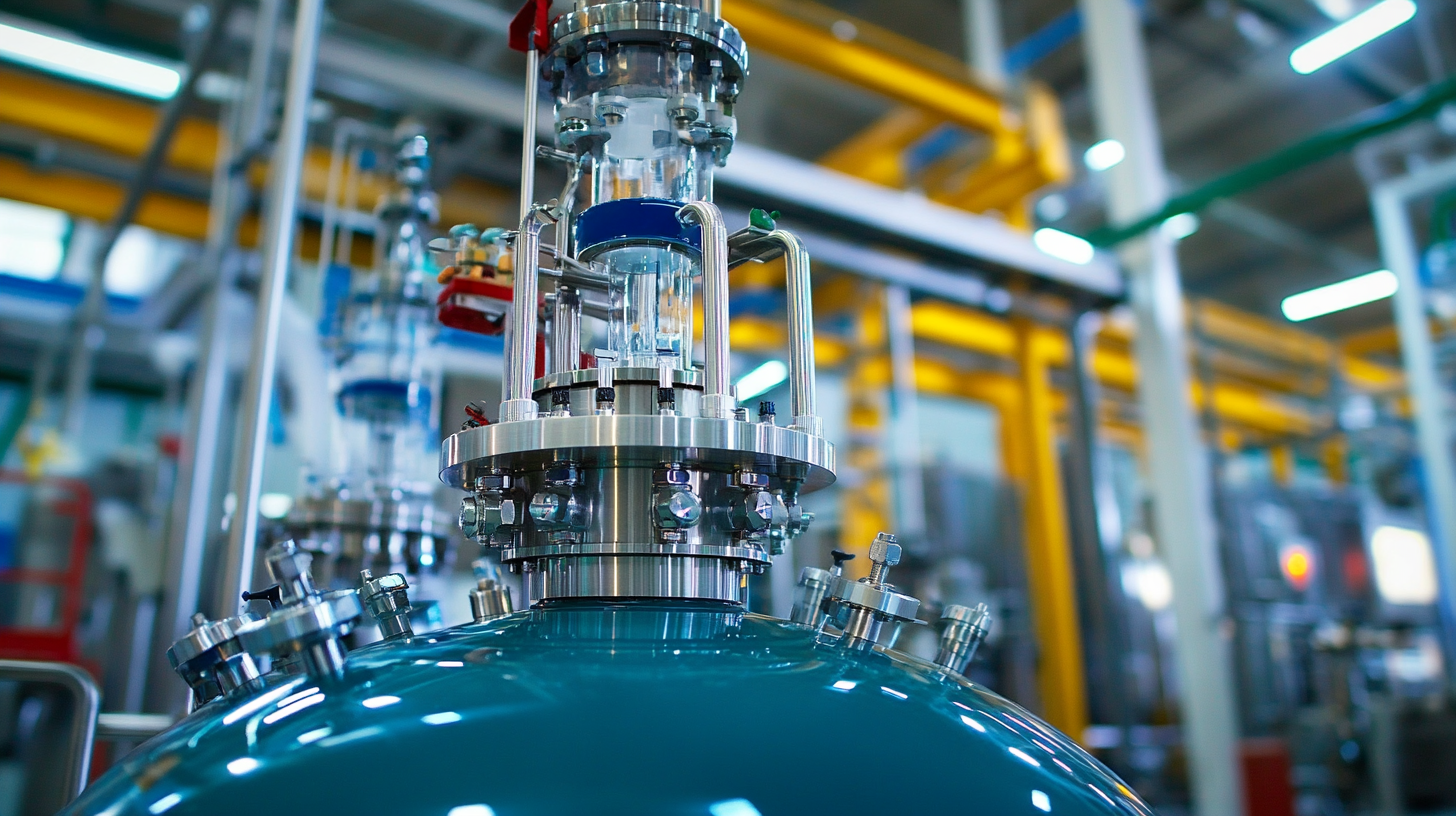

In today's fast-paced industrial landscape, the efficiency and quality of production processes can significantly impact a business's success. One of the critical components that play a vital role in many manufacturing operations is the Chemical Mixture Machine. Selecting the right machine not only enhances the overall productivity but also ensures consistency and precision in the chemical formulation. In this blog, we will delve into five compelling reasons why investing in the best Chemical Mixture Machine is crucial for your business. From improving operational efficiency to complying with safety standards, understanding the advantages of the right equipment can lead to enhanced performance and profitability, giving your company a competitive edge in the market. Join us as we explore the essential factors that can guide your decision-making process in choosing the ideal chemical mixing solution for your needs.

In today's fast-paced industrial environment, precision in chemical mixing plays a pivotal role in boosting business efficiency. The demand for exact formulations has never been higher, as even the slightest deviations in chemical mixtures can lead to significant consequences, including product inefficiency and increased waste. Innovations in precision engineering, such as those seen in advancements with proton exchange membrane fuel cells, demonstrate how meticulous control over chemical compositions can enhance performance. These technologies not only improve product outcomes but also streamline operational processes, emphasizing the need for businesses to invest in high-quality chemical mixture machines.

Furthermore, the integration of artificial intelligence in chemistry is revolutionizing how precision is achieved in chemical processes. AI-driven systems can optimize mixing parameters in real-time, ensuring that products are consistent and meet rigorous standards. This efficiency translates into cost savings and higher product reliability, which are critical for competitive advantage. As industries move toward more automated and data-driven approaches, the importance of precision in chemical mixing becomes increasingly clear, reinforcing the necessity of selecting advanced chemical mixture machines that support these innovations.

In the competitive landscape of chemical production, selecting the optimal mixing machine is critical. This chart illustrates the importance of five key factors that businesses should consider when choosing a chemical mixture machine, underscoring the need for precision in chemical mixing to enhance overall business efficiency.

Advanced technology in mixing machines has revolutionized the chemical industry, significantly enhancing productivity across various sectors. According to a report by Research and Markets, the global market for mixing equipment is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by advancements in automation and process optimization. Modern chemical mixture machines utilize sophisticated algorithms and real-time data analytics to achieve precise formulations and consistent product quality, reducing the potential for human error and batch-to-batch variability.

Additionally, the integration of IoT (Internet of Things) technology allows manufacturers to monitor mixing processes remotely. A survey conducted by the National Association of Manufacturers indicated that 58% of businesses utilizing smart mixing technology reported a significant increase in operational efficiency. This capability not only streamlines production workflows but also minimizes downtime, as predictive maintenance can be implemented to address potential issues before they disrupt the manufacturing process. With these advancements, investing in the best chemical mixture machine is not just a choice; it's a necessity for businesses looking to stay competitive in a rapidly evolving marketplace.

| Feature | Benefit | Impact on Productivity | Cost Savings (%) |

|---|---|---|---|

| Automated Mixing Controls | Increased precision in mixing | Reduces error rates and enhances quality | 15% |

| Energy Efficiency | Lower power consumption | Decreases operational costs | 20% |

| User-Friendly Interface | Easier for staff to operate | Improves employee efficiency | 10% |

| Integration with ERP Systems | Real-time data tracking | Enhances decision-making | 12% |

| Robust Safety Features | Minimizes workplace hazards | Reduces downtime from accidents | 18% |

Investing in a high-quality chemical mixture machine can significantly enhance the cost-effectiveness of manufacturing processes. According to a report by Grand View Research, the global mixture machine market is projected to reach $3.2 billion by 2025, driven by increased demand for efficiency and precision in chemical production. The right machinery not only streamlines operations but also minimizes waste, enabling businesses to reduce their overall production costs. For instance, advanced mixing technologies can lead to a reduction in ingredient usage by up to 20%, translating into substantial savings over time.

Moreover, the long-term durability of high-quality chemical mixture machines contributes to their cost-effectiveness. Data from MarketsandMarkets indicates that companies can save an average of 15-30% on maintenance costs when opting for premium equipment compared to lower-quality alternatives. These machines often feature superior materials and innovative designs that extend their lifecycle and reliability. By prioritizing quality, businesses not only invest in immediate savings but also set a foundation for sustainable growth and improved operational efficiency.

When it comes to chemical mixture machines, safety is paramount. According to a report by the Occupational Safety and Health Administration (OSHA), nearly 4,500 workplace fatalities occur each year in the United States, with many resulting from equipment-related incidents. Thus, investing in advanced mixing machines equipped with comprehensive safety features can significantly minimize the risk of accidents. Modern machines are now equipped with automatic shut-off mechanisms, pressure sensors, and overload protection, ensuring that operators are safeguarded against mechanical failures.

Moreover, the incorporation of fail-safe designs not only protects workers but also preserves the integrity of your investment. The American Society of Safety Professionals (ASSP) notes that organizations can save up to $4 for every $1 spent on safety investments. This statistic highlights the financial incentive behind prioritizing safety in your operations. By choosing mixing machines that meet stringent safety standards, businesses can reduce downtime, avoid costly accidents, and cultivate a safety-first culture. Investing in the right machinery not only ensures compliance with regulations but also fosters a productive and secure work environment, ultimately benefiting both employees and the bottom line.

Choosing the right chemical mixture machine for your business is crucial, especially when versatility and customization are at the forefront of your operational strategy. The ability to adapt equipment to meet diverse business needs can significantly enhance productivity and efficiency. For instance, companies that require quick reconfiguration of their machinery can reduce downtime, ensuring that production remains uninterrupted while responding to market demands.

When exploring your options, consider the types of materials you'll be processing and the flavors or formulations you aim to create. Choosing equipment that allows for easy adjustments not only meets current needs but also prepares your business for future growth. This adaptability is akin to the way certain equipment in varied industries has evolved to optimize efficiency, enabling manufacturers to stay competitive.

Tip: Always look for machines that offer customizable settings and configurations. This feature can save you time and resources in the long run. Additionally, investing in modern technology that supports automation can further enhance operational versatility. By prioritizing equipment that meets your specific business requirements, you set the stage for sustained growth and innovation.